QT10-15 Automatic concrete colored paver block making machine

Main advantages for QT10-15hydraulic interlocking block making machine

1. QT10-15 is a fully automatic PLC (3 control cores)with hydraulic system brick machineThis machine no need worker control, easy operation

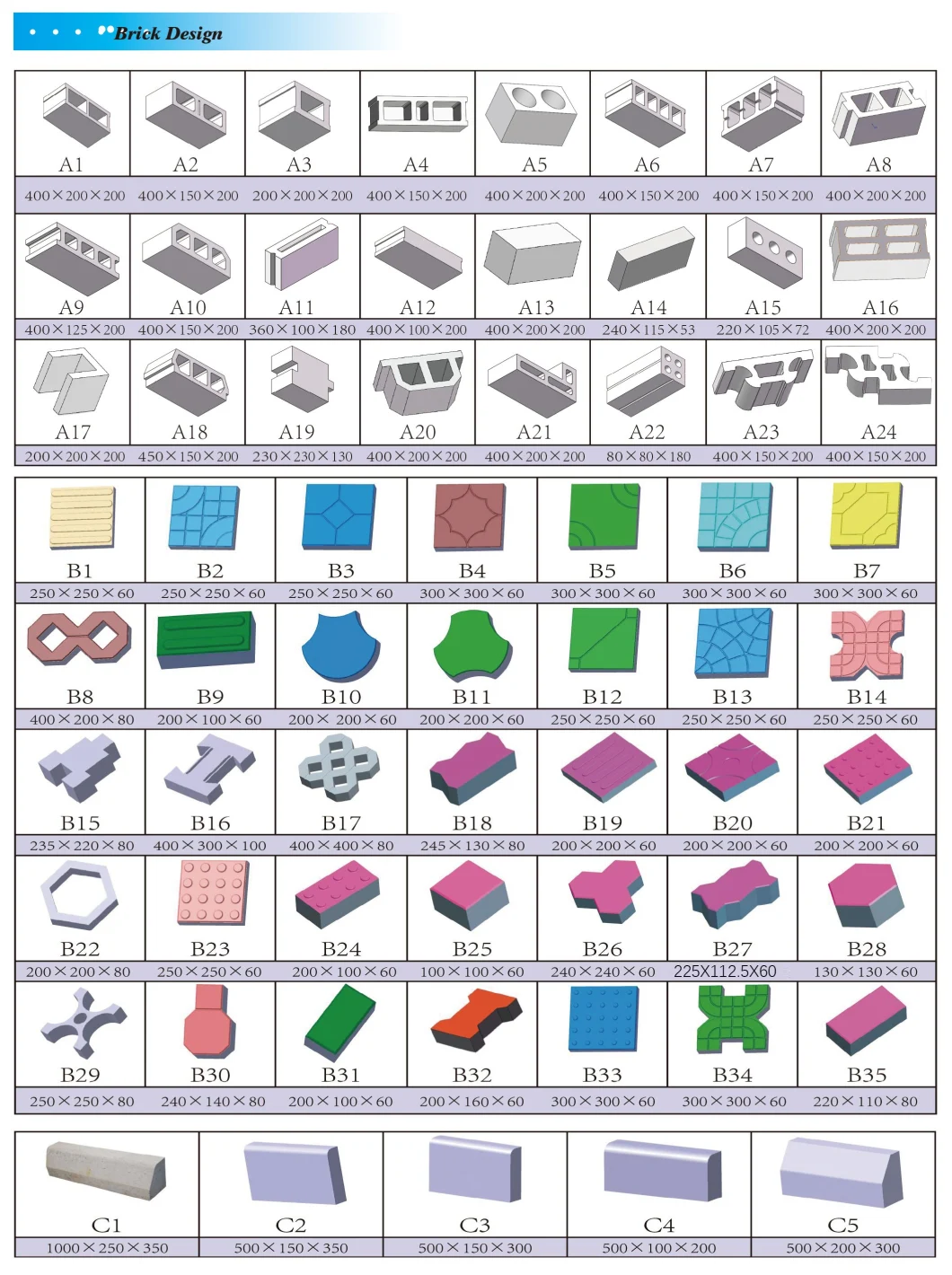

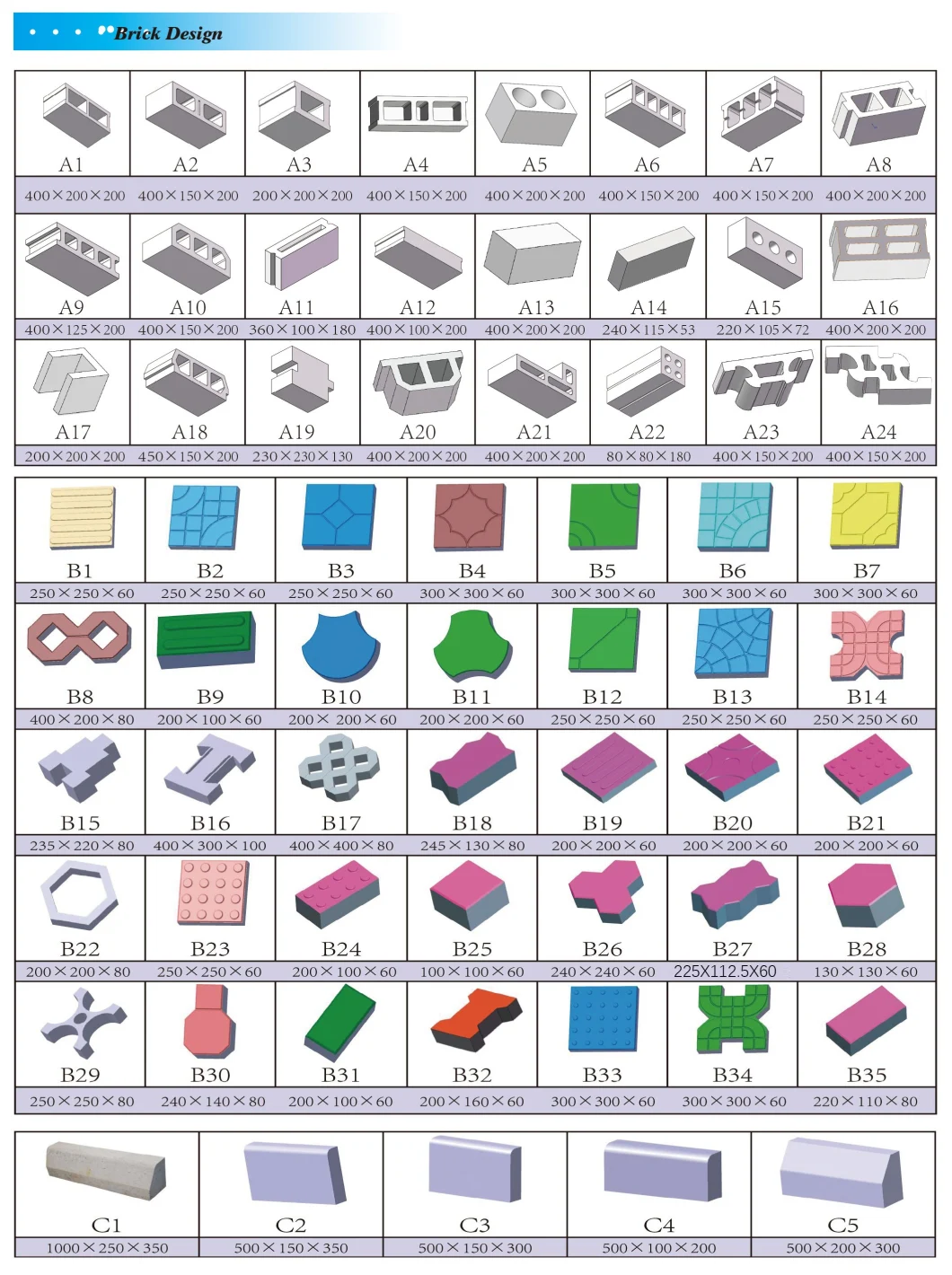

2. QT10-15 could produce different size and shape hollow block, solid block, interlocking brick, paving brick, color face paver and curbstones

3. QT10-15 is classical big machine, it could work durable and stably

4. QT10-15 has bigger vibration force and better hydraulic system, it could produce faster and better quality blocks.

5. Big production capacity. Max. production capacity: 300CBM standard hollow blocks per 8 hours.

1)Main components display of QT10-15 full automatic hydraulic block making machine

1. QT10-15 is a fully automatic PLC (3 control cores)with hydraulic system brick machineThis machine no need worker control, easy operation

2. QT10-15 could produce different size and shape hollow block, solid block, interlocking brick, paving brick, color face paver and curbstones

3. QT10-15 is classical big machine, it could work durable and stably

4. QT10-15 has bigger vibration force and better hydraulic system, it could produce faster and better quality blocks.

5. Big production capacity. Max. production capacity: 300CBM standard hollow blocks per 8 hours.

1)Main components display of QT10-15 full automatic hydraulic block making machine

| A | QT10-15 Host brick machine a. Automatic pallet system b. Automatic material feeding system |

| B | Block receiver |

| C | Stacker, it could layer 4-5 pallets blocks |

| D | 8m conveyor |

| E | JS750 Mixer bigger power, 38.6KW |

| F | Batching machine PLD 1200, power, 12KW |

| Color feeder system (Optional) | QT10-15 Color feeder machine--Automatic hydraulic machine |

| Color mixer--1.5m; 11kw | |

| 6m conveyor |

(2)Quality of main parts:

A: This new design could ensure head mold could up and down in level, even if meet small sand and stones, protect machine.

B: Hopper outlet mouth new design, it could avoid material block (vibration could often make material in hopper block).

C: New technology, reduce control arm travel length, increase QT10-15 machine production speed, increase production capacity

D:The guid posts are chrome-plating treatment,and all outer jacket of guid posts are made by high quality copper.These keep partsof the machine smoothly use long time .

E: Head mold famous brand thicker steel material, it can use longer time.Axle vibration box, it could supply bigger vibration force, make blocks better quality and save cement.

F: Unique material preading machine with special arch rod to force steel forks in big force.Make the material preading fast and evenly.And all steel on the arch rod and forks aremade by hot treatment to keep long time use.

(3)QT8-15 Automatic cement brick plant technical information:

| Molding cycle | 15s |

| Vibration frequency | 4600-5200hz |

| Vibration force | 90kn |

| Rated pressure | 21mpa |

| Host brick machine size | 5360(L)×2830(W)×2820(H)mm |

| Net Weight | 6000kg |

| Pallet size | 1100-8700-25mm |

2.QT10-15 block machine production capacity show:

| Item | Block | Production capacity |

| 1 | Hollow/Solid block 400-200-200mm | 10 pcs/mold 19200 pcs/8h |

| 2 | Solid block 240*115*53mm | 52pcs/mold 99800 pcs/8h |

| 3 | Holland paver 200-100-60mm | 35 pcs/mold 67200 pcs/8h |

Block and Paving Brick Design for your reference:

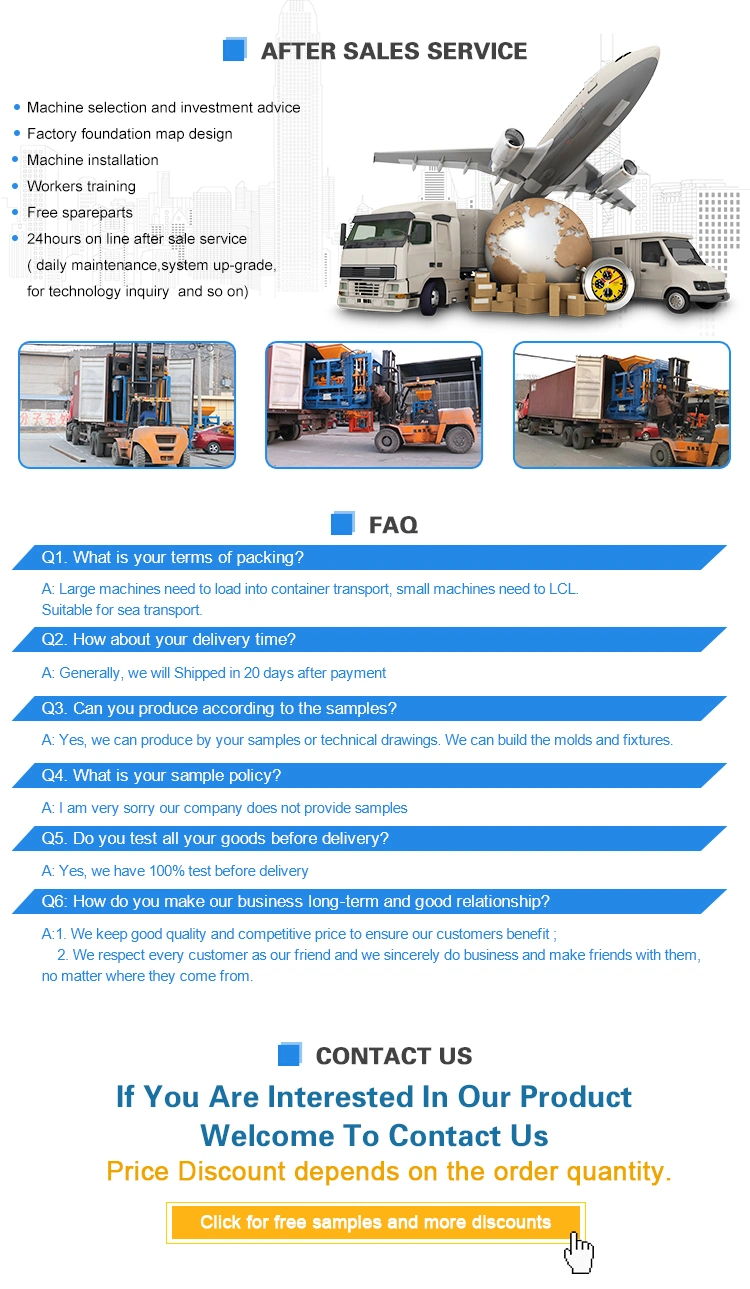

3.QT10-15 automatic hydraulic paver brick making machine service

Pre-Sales Service:

1. Inquiry and consulting support.

2.Sample testing support.

3. View our Factory.

After-Sales Service:

1.Training how to instal the machine, training how to use the machine.

2. Engineers available to service machinery overseas.

3.We will reply you for your inquiry in 24 hours.

4.After sending, we will track the products for you once every two days, until you get the products.

When you got the machine test them, and give me a feedback.

If you have any questions about the problem, contact with us, we will offer the solve way for you

5.Recommended block machine video link :

3.QT10-15 automatic hydraulic paver brick making machine service

Pre-Sales Service:

1. Inquiry and consulting support.

2.Sample testing support.

3. View our Factory.

After-Sales Service:

1.Training how to instal the machine, training how to use the machine.

2. Engineers available to service machinery overseas.

3.We will reply you for your inquiry in 24 hours.

4.After sending, we will track the products for you once every two days, until you get the products.

When you got the machine test them, and give me a feedback.

If you have any questions about the problem, contact with us, we will offer the solve way for you

5.Recommended block machine video link :

| QT4-15 brick machine video link | https://youtu.be/S-jXNj21DP8 |

| QT10-15 hollow block machine video link | https://youtu.be/CfXshCxbooI |

| QT4-18 hydraulic block machine | https://youtu.be/sAgSkQjtgmY |

| QT4-24B semi auto brick machine | https://youtu.be/gGXL4XK4KoM |

| QT4-30A mobile brick machine | https://youtu.be/MoovhoR4x_Y |

Contact information: